Scraping By

Adaptive Clay Carving for Performative Tiles

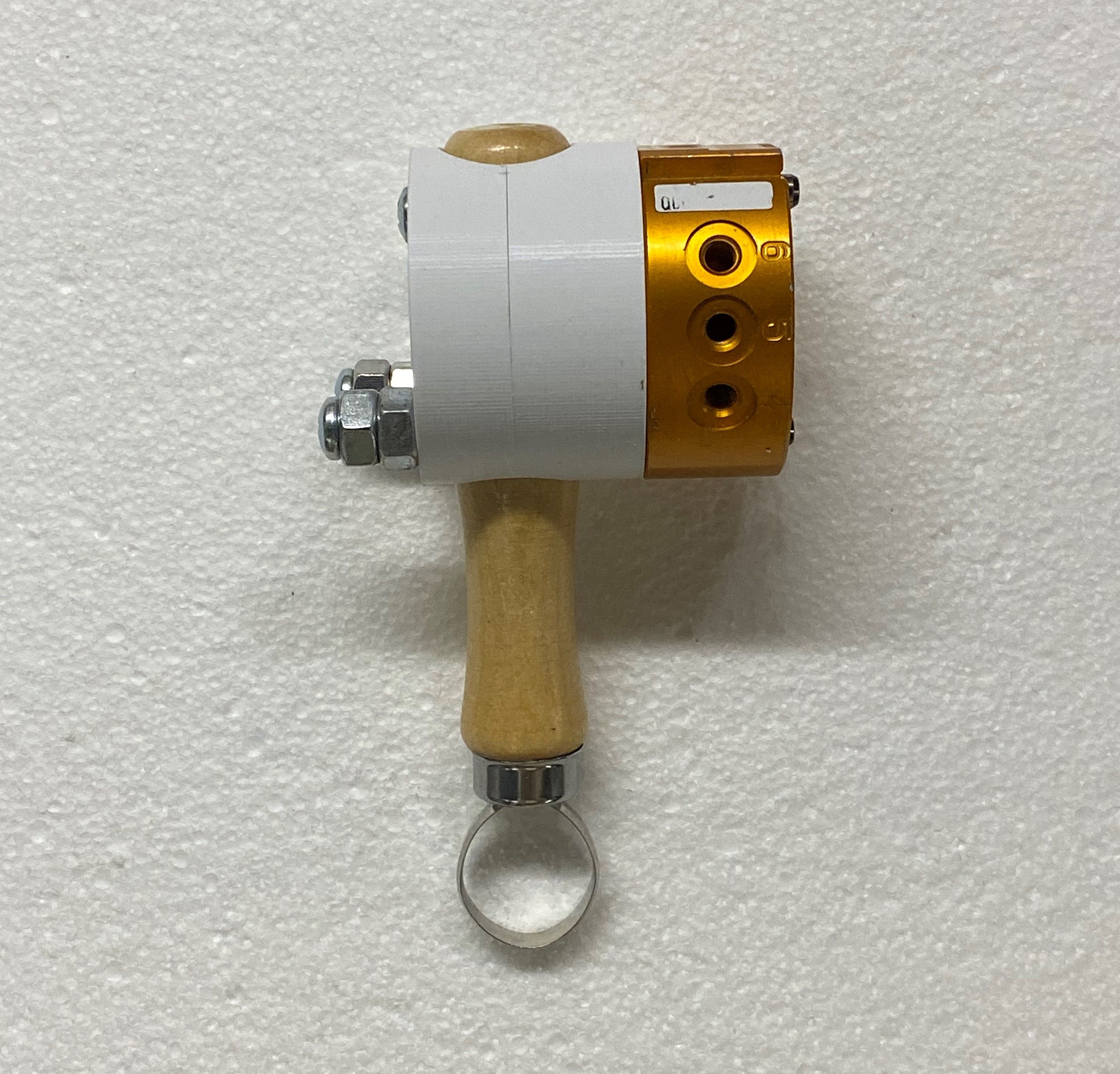

An interest began in the introduction of a feedback loop into digital fabrication that would allow for a production process to be made adaptive; as in, the machine would able to receive information regarding the material it is operating on and make adjustments throughout the process. We wanted to explore carving because it has a type of humaneness that is inherent in the act of carving, so there is this interesting dynamic of automating a very human process, but also humanizing a very digital process.

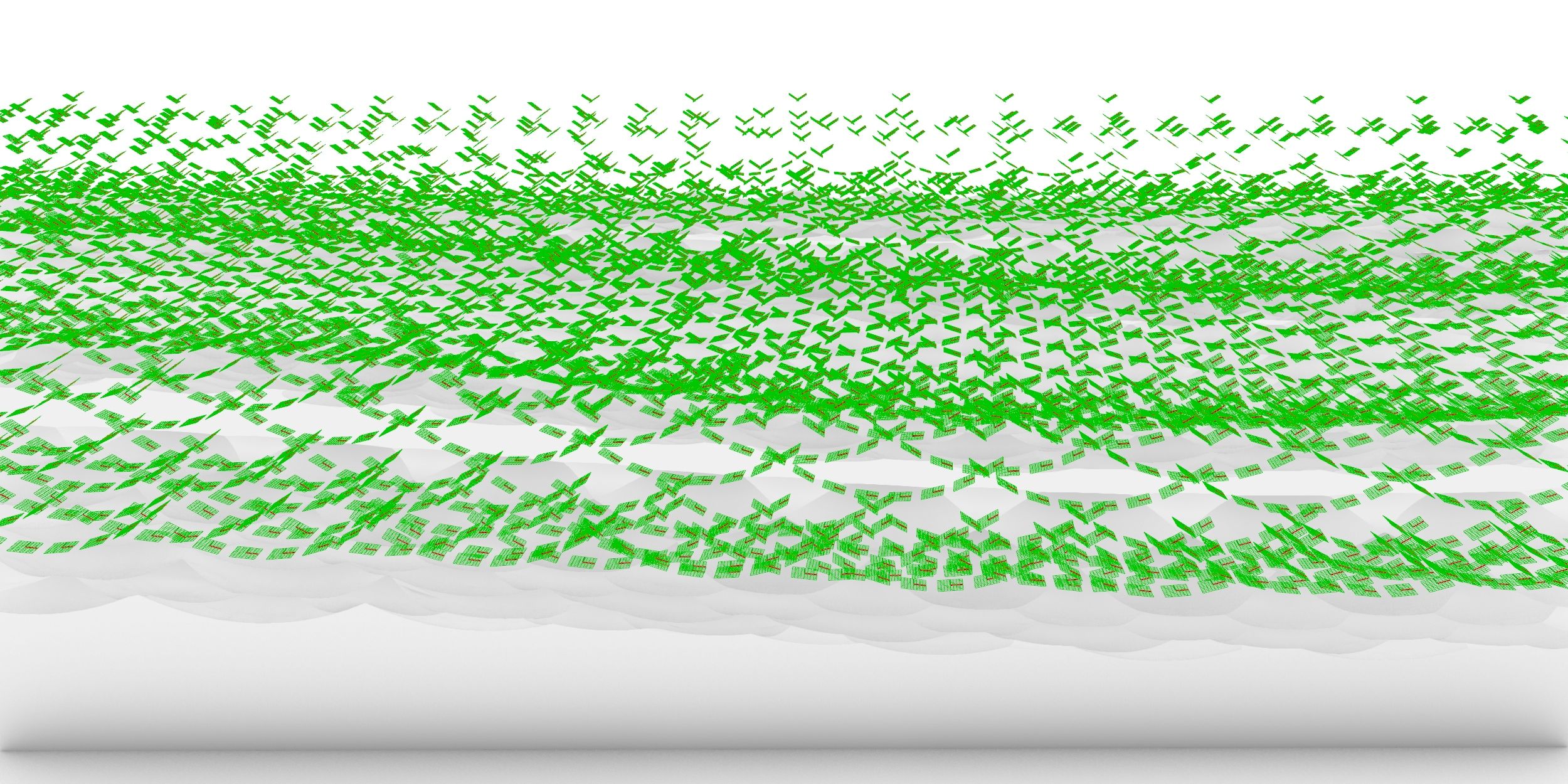

The main research alignment for this assignment is allowing the machine to generate its own tool-path with any input surface and target surface. As the clay is being carved, there is a difference between what the actual state of the clay is, versus the ideal state of the clay after the carving motion, with an upper limit to the step-down increment. The scanning cycle placed between carving cycles would allow for the machine to adjust its tool-path to adapt for the tolerances caused by its previous step, resulting in a more balanced carving pattern, and also ultimately reach its target surface.