Wire Printing

From Column to Truss

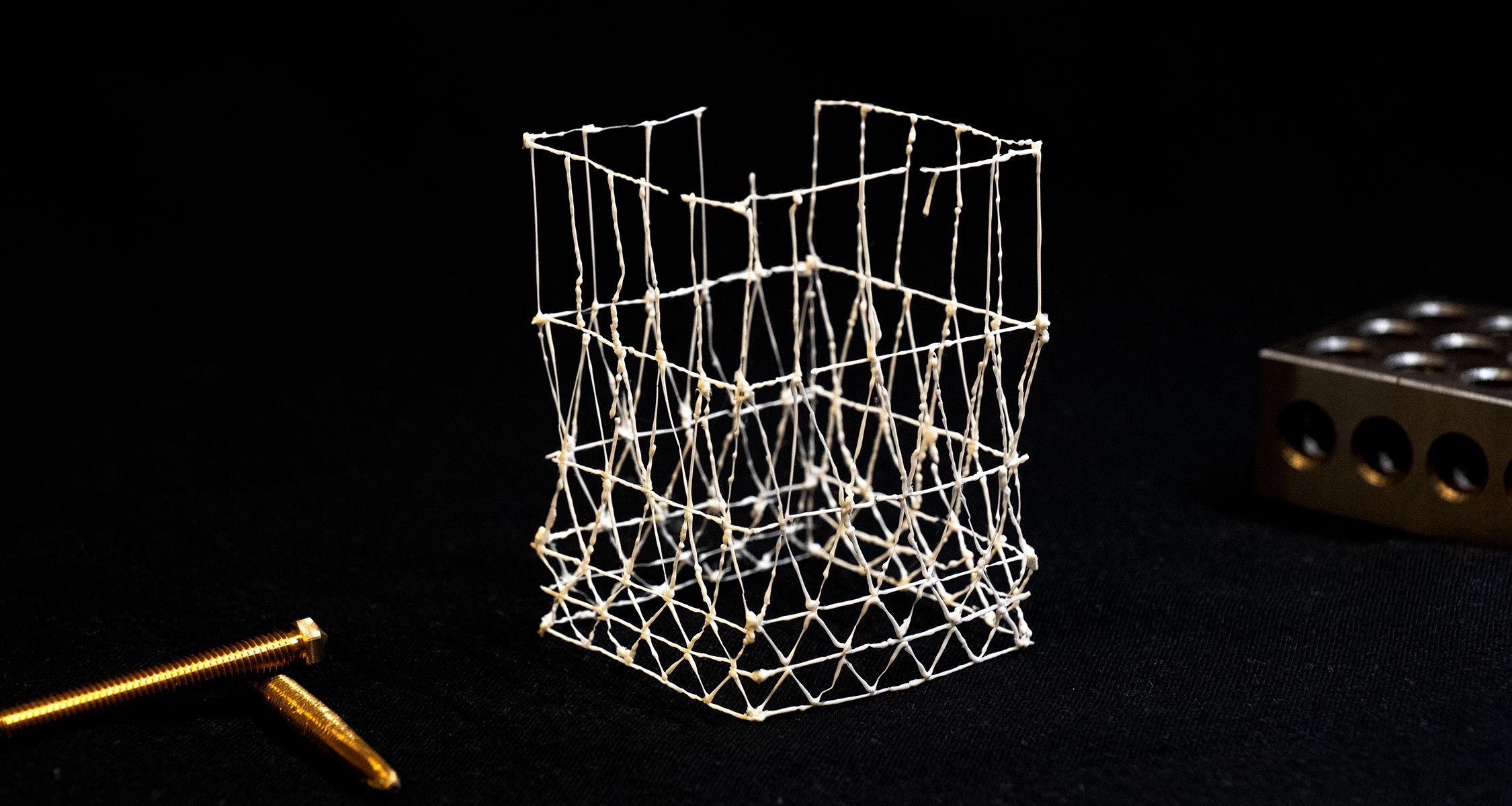

The project: Wire printing: From column to truss, is inspired by the Simple factory building in Singapore, in which the truss member gradually elongates, and eventually becomes a vertical column.

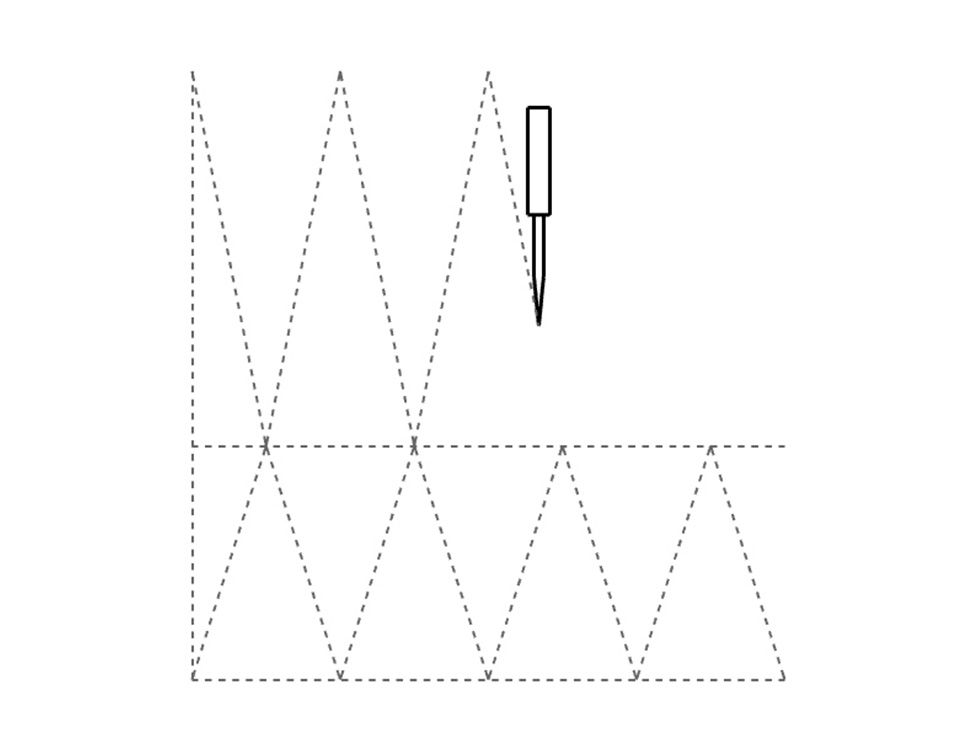

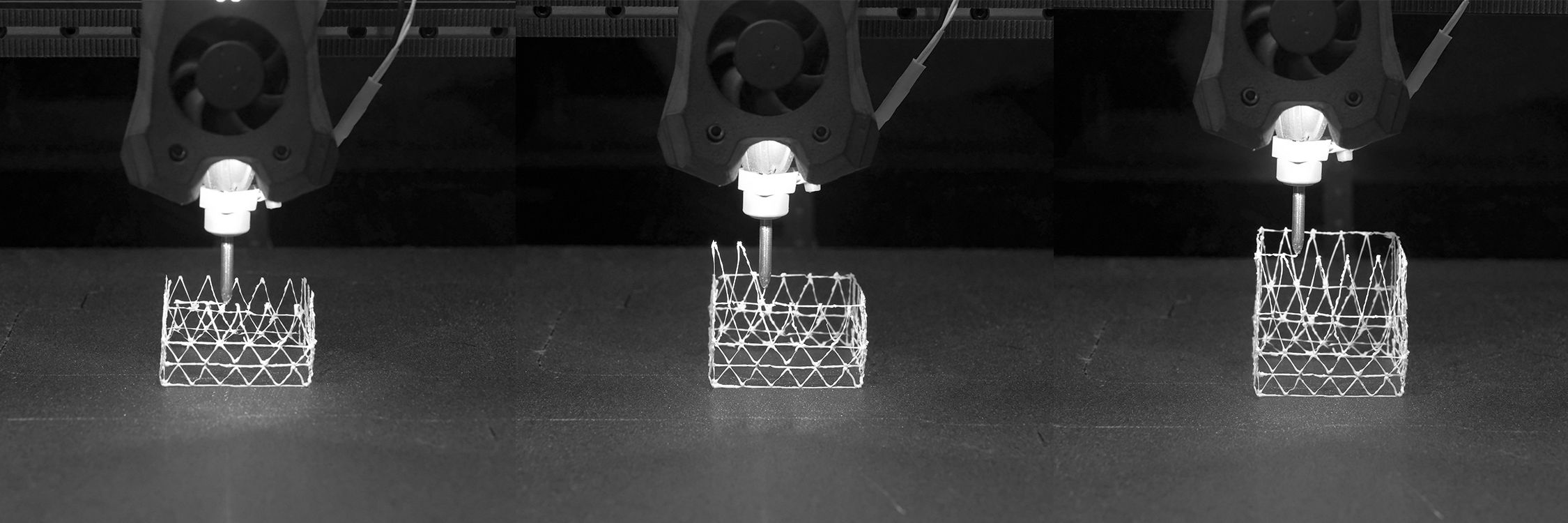

We hope to further the exploration of wire printing, which is first developed by a team at MIT in 2014. Also, we hope to address the issues raised by the team, including the cooling and collision issues. For the collision issues, a customized, pointy nozzle is made to ensure the steep diagonals are printed without collision with the nozzle. For the cooling issue, between every movement, a pause of 8 seconds is added to form a node that better connects the hanging strings.

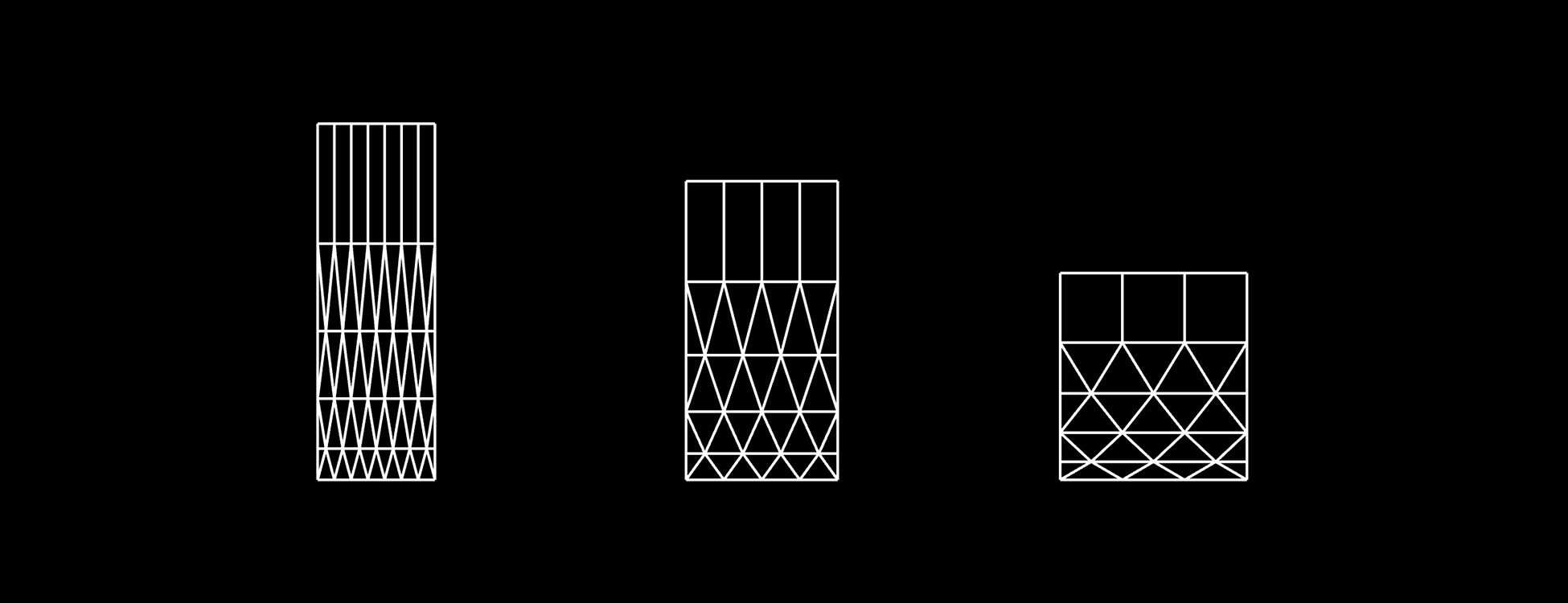

The print begins with a mildly angled diagonal member. Then, layer by layer, the angle gets steeper, until it becomes a vertical member. While the angles increase, the nozzle is more likely to collide with the printed plastic, but the difficulty in printing decreases as the vertical member is less likely to tilt, compared to an unsupported diagonal member. The gradient of the angled diagonals reveals the complexity of wire printing optimization.