Bloq

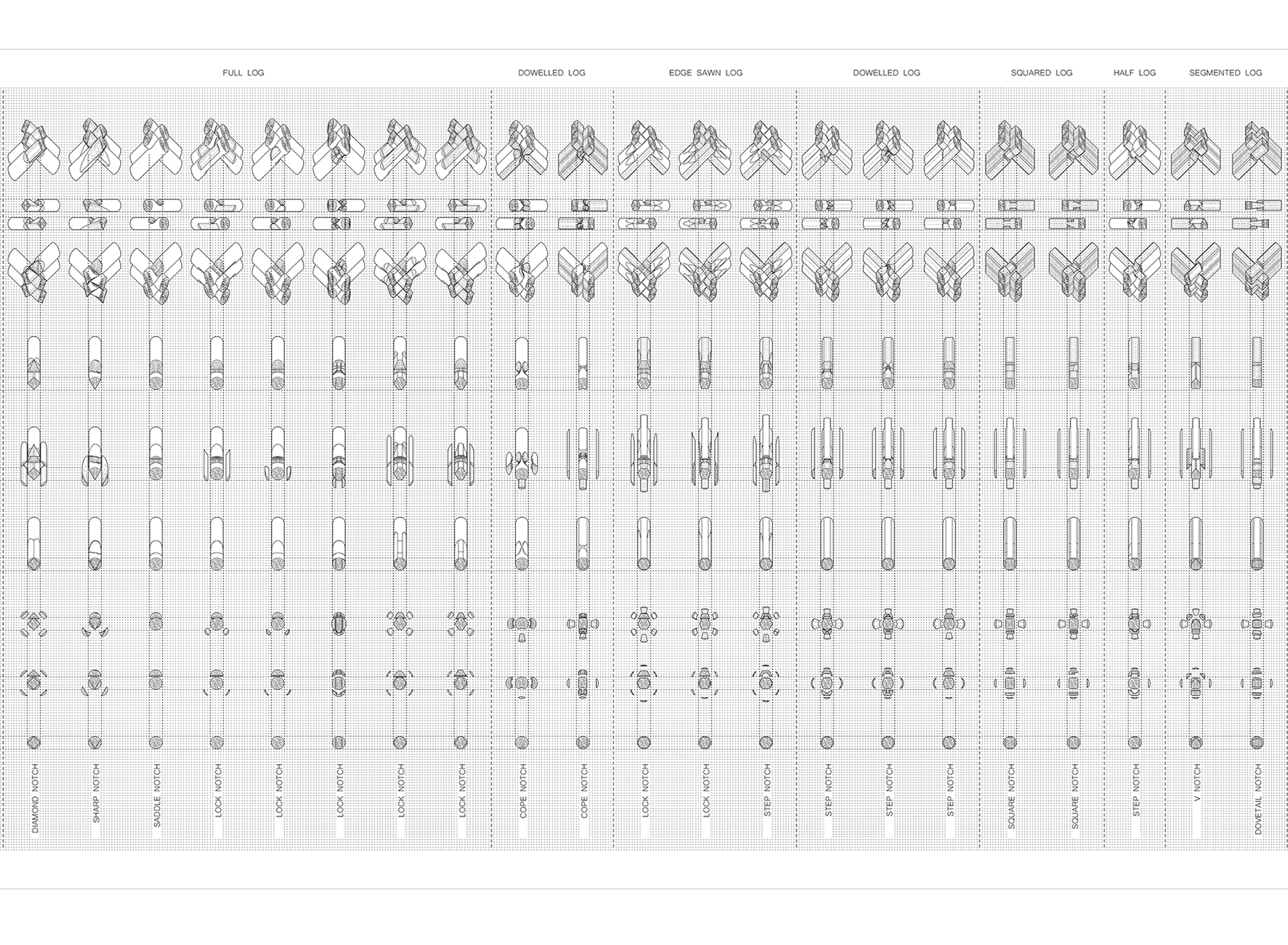

Slicer Patterning for Anisotropic Materials

Modern sawmills rely on machine vision and computational analysis to determine how to optimally cut a stock of wood into standardized cross sections of dimensional lumber that minimize material waste while maximizing profit. By imaging the end cut of a log to determine the orientation of the wood grain, sawmills can strategically plan their cuts in order to can avoid deformation in the length of a timber element. Advances in X-Ray CT scanning have allowed sawmills to digitally reconstruct the inside of wooden logs pre-cutting in order to detect the precise location of interior knots and other deformities in order to strategize how to avoid aesthetic and structural defects.

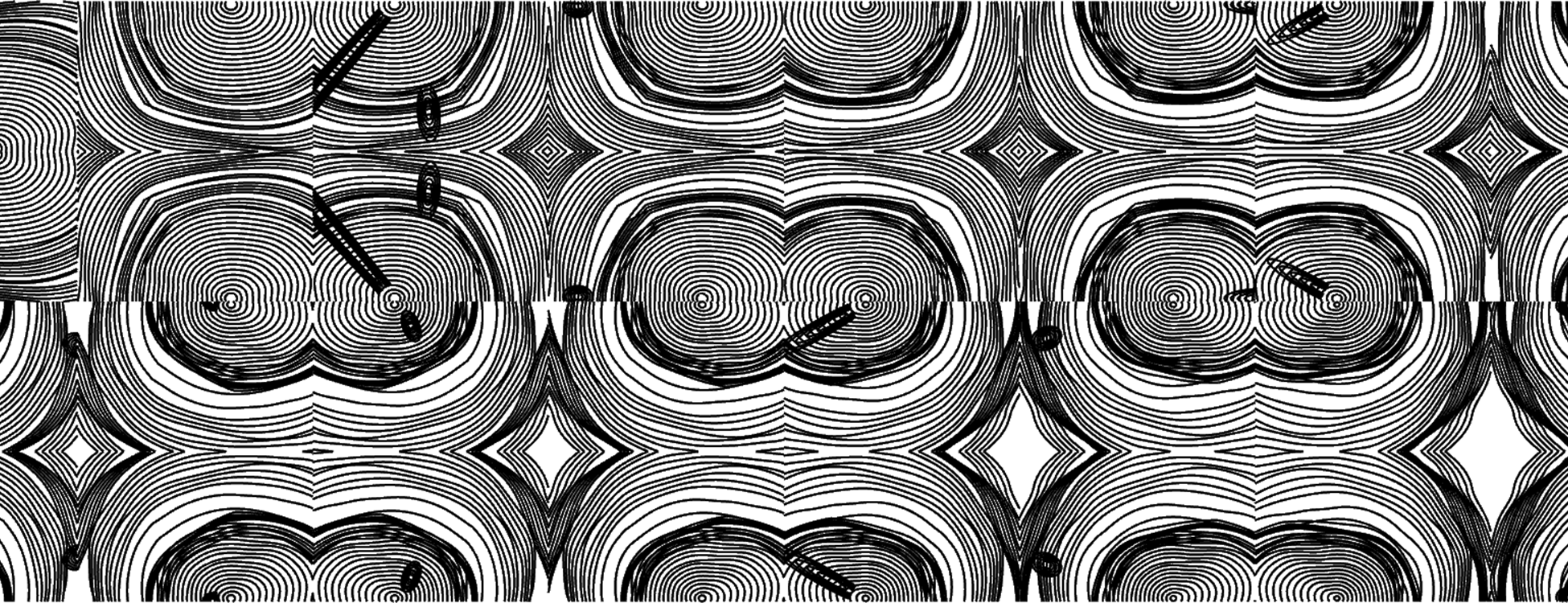

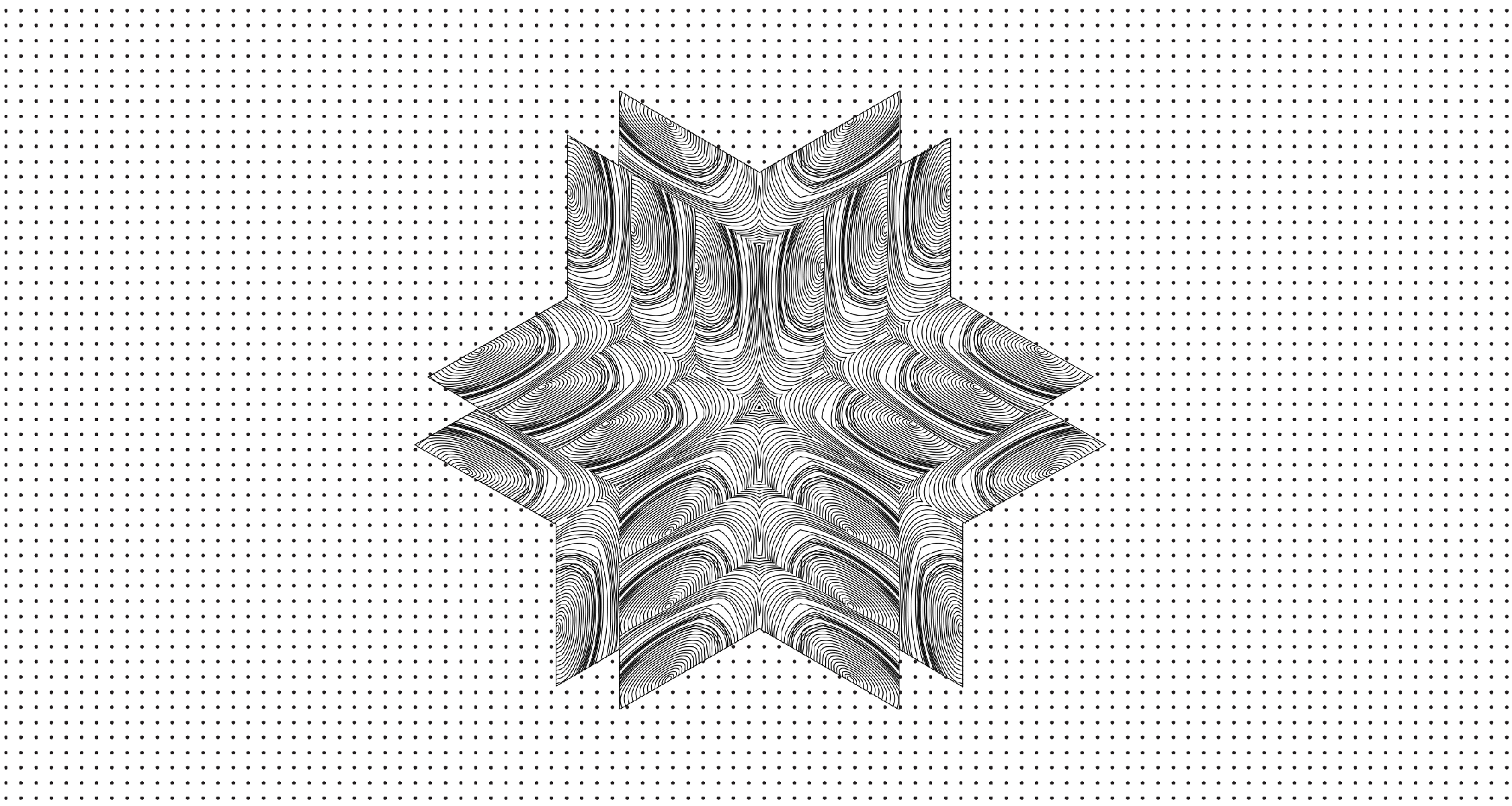

However, despite how widespread these types workflows are in the timber industry, new visualization methods have not been deployed as a generative tool that can aid in the design process. This project investigates how these processes can be leveraged to generate aesthetic (and potentially financial) value in the irregularities and deformations found in wood through a slicer visualization tool that mirrors and tiles cut patterns taken from a tomographic model of a log. By visualizing the natural wood grain, BLOQ can explore the full space of potential bookmatching patterns in a stock of wood which can then be used to saw, refine and assemble a tiled repeating pattern for architectural scale applications.