Textile Test

Playful Variations of 3D Printed Textiles

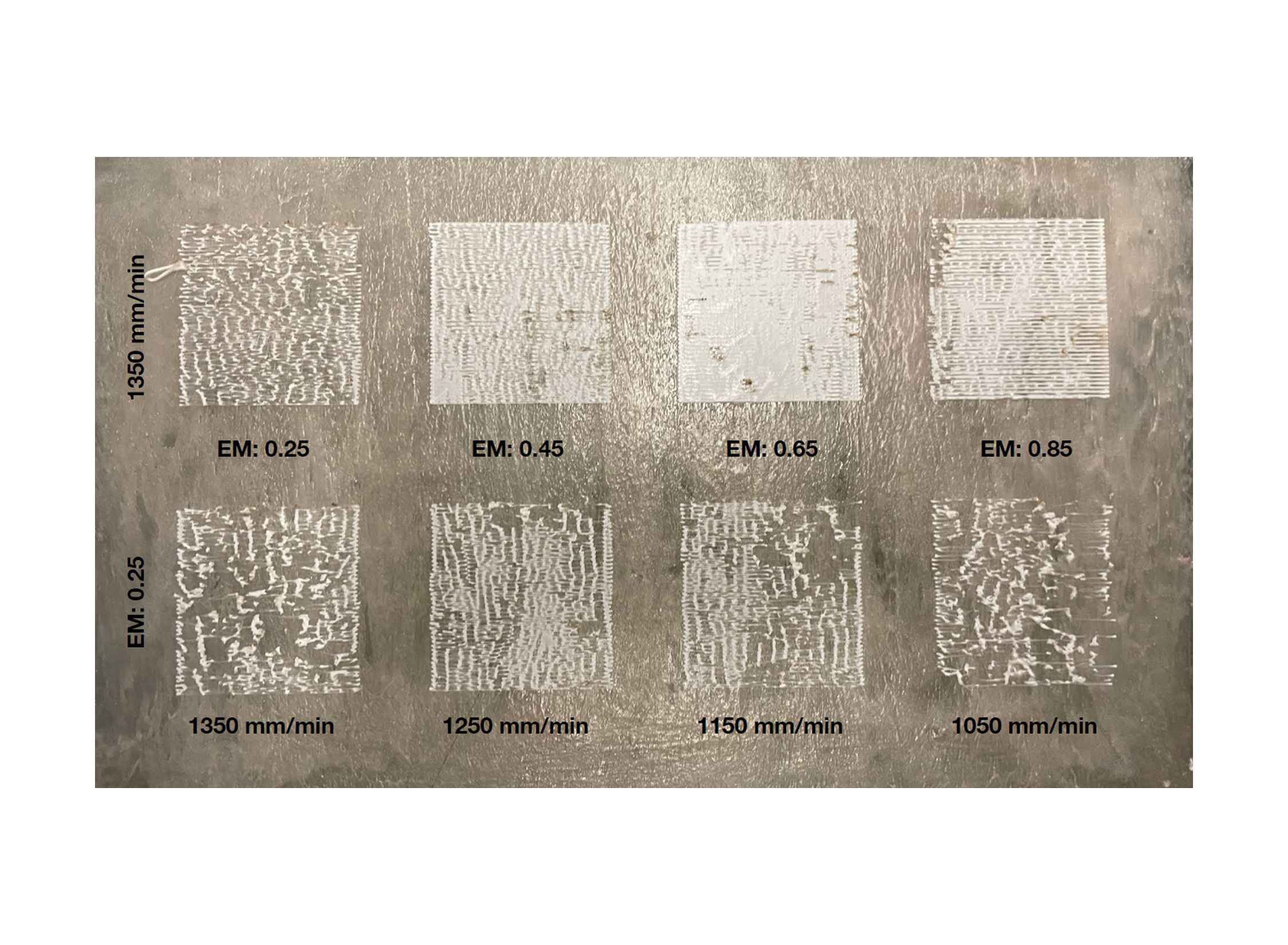

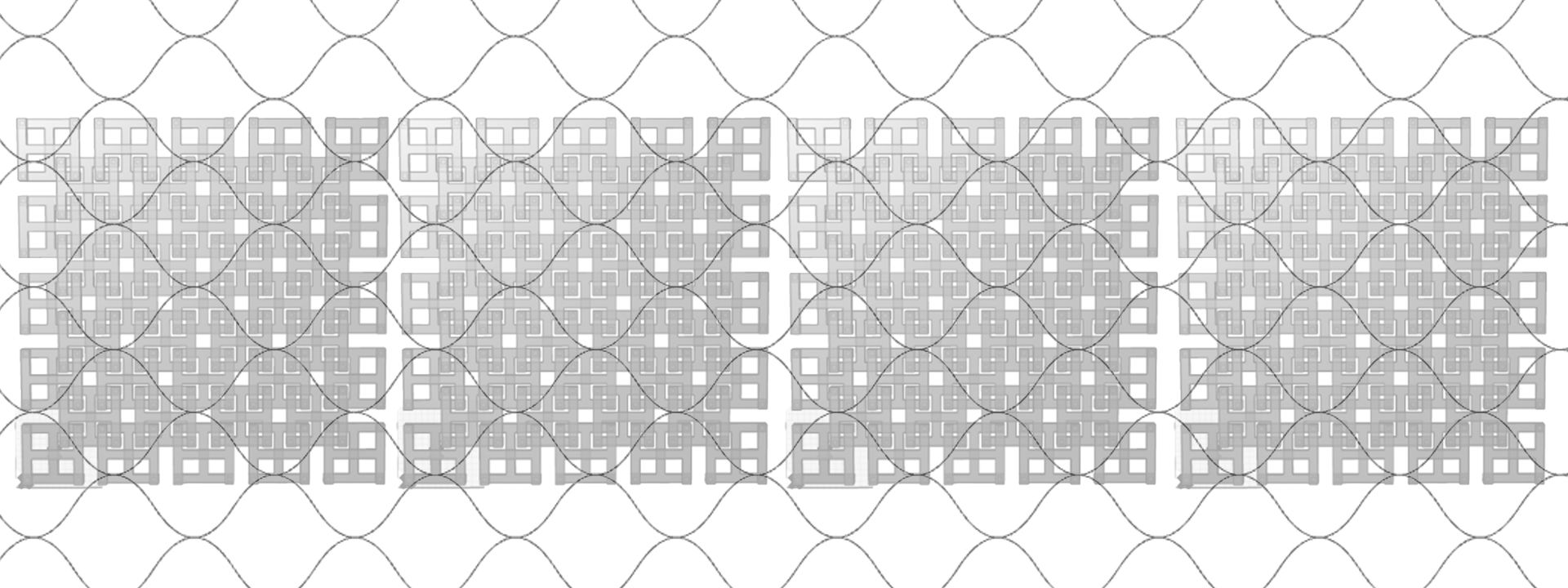

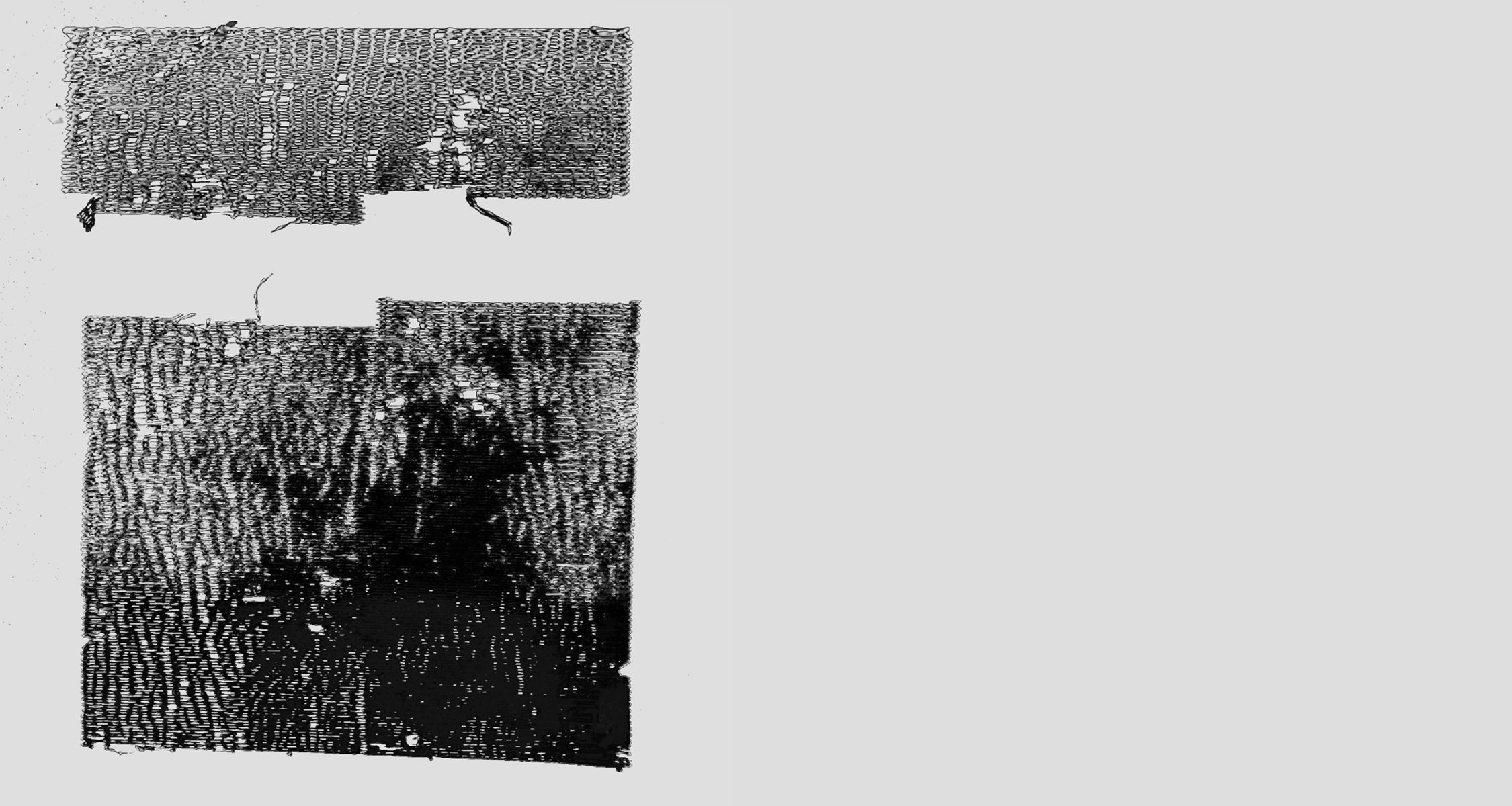

In our project, Textile Test, we aimed to utilize a unique geometrical design for 3D printing, generating our own unique G-code. We initially took inspiration from Kirigami structures, which reforms 2d planes into 3d structures by cutting complex patterns. This led our research to the MIT media lab which demonstrates DefeXtiles, utilizing motion of a printer rather than printing a large string of material—in other words, leveraging under-extrusion of 3D printing filament to create breathable and flexible textile structures. We used custom G-code to create several iterations of the woven flat-sheet prototypes, testing variations in elements such as folding/unfolding and heat. In varying the extrusion direction, feed rate, multiplier, and printer model, we can test what method proves to be most beneficial in creating this flexible structure. Through this approach we have sought after a more flexible and accessible form of 3d printing that can be implemented in fabric, origami-like geometric shapes, and architectural designs. Additionally, this method combined with post-processing techniques such as heat-bonding, sewing, and de-pleating can increase the applications of which these textiles have uses, allowing for further control and manipulation of the textiles.