Design with Gravity

Non-planar Printing with Geometry Frames

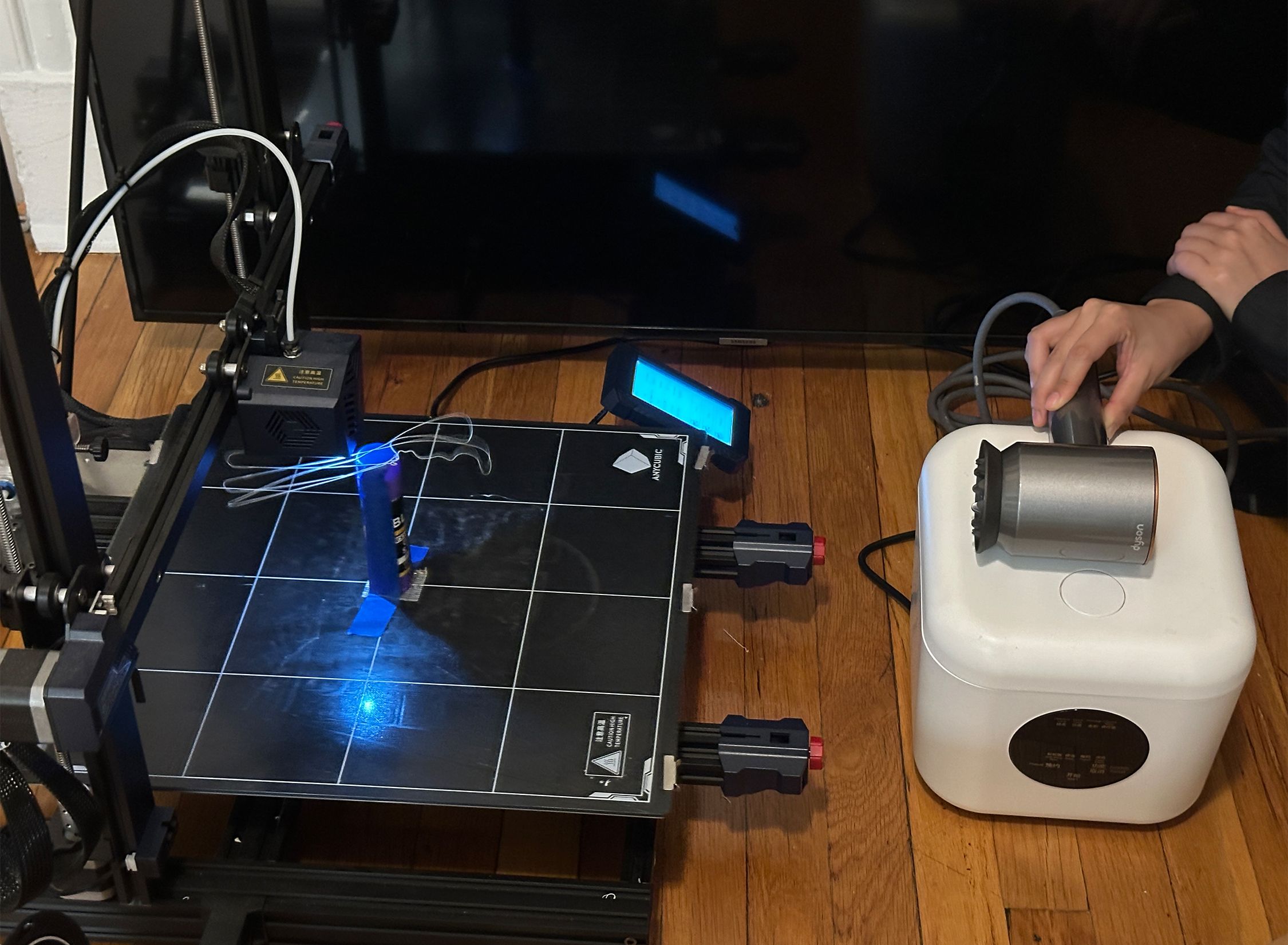

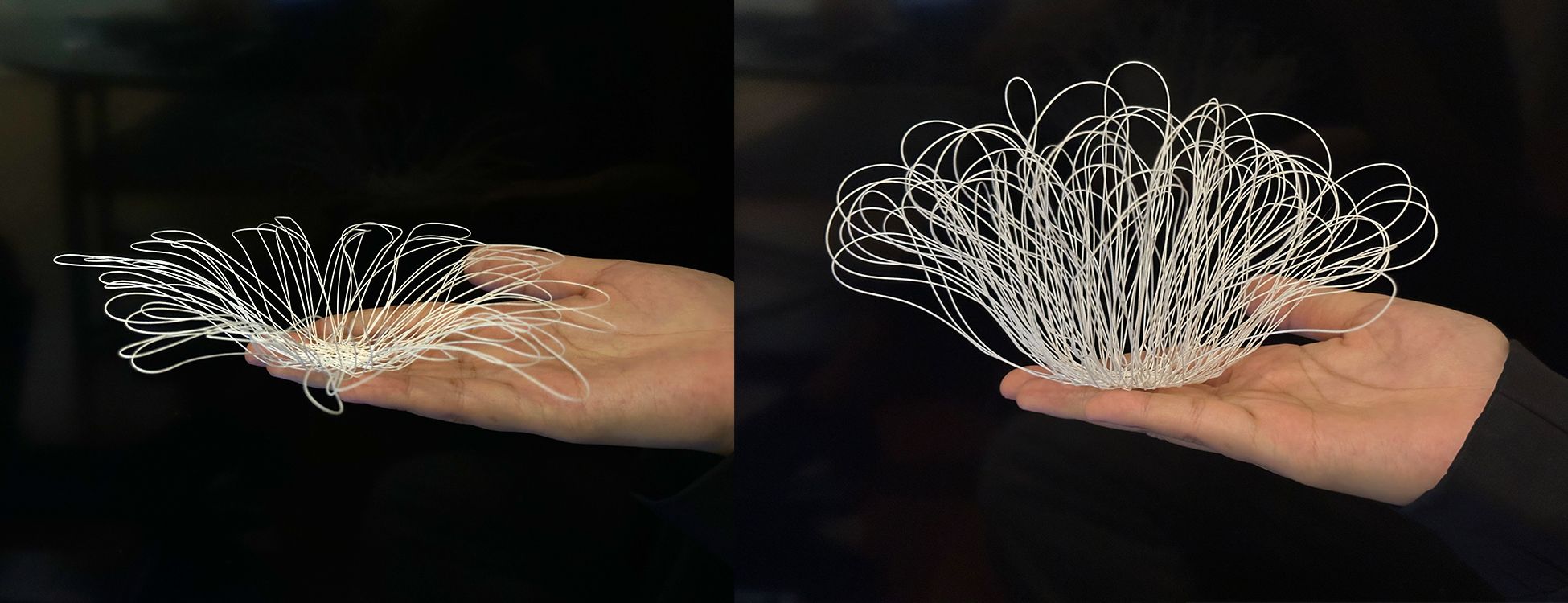

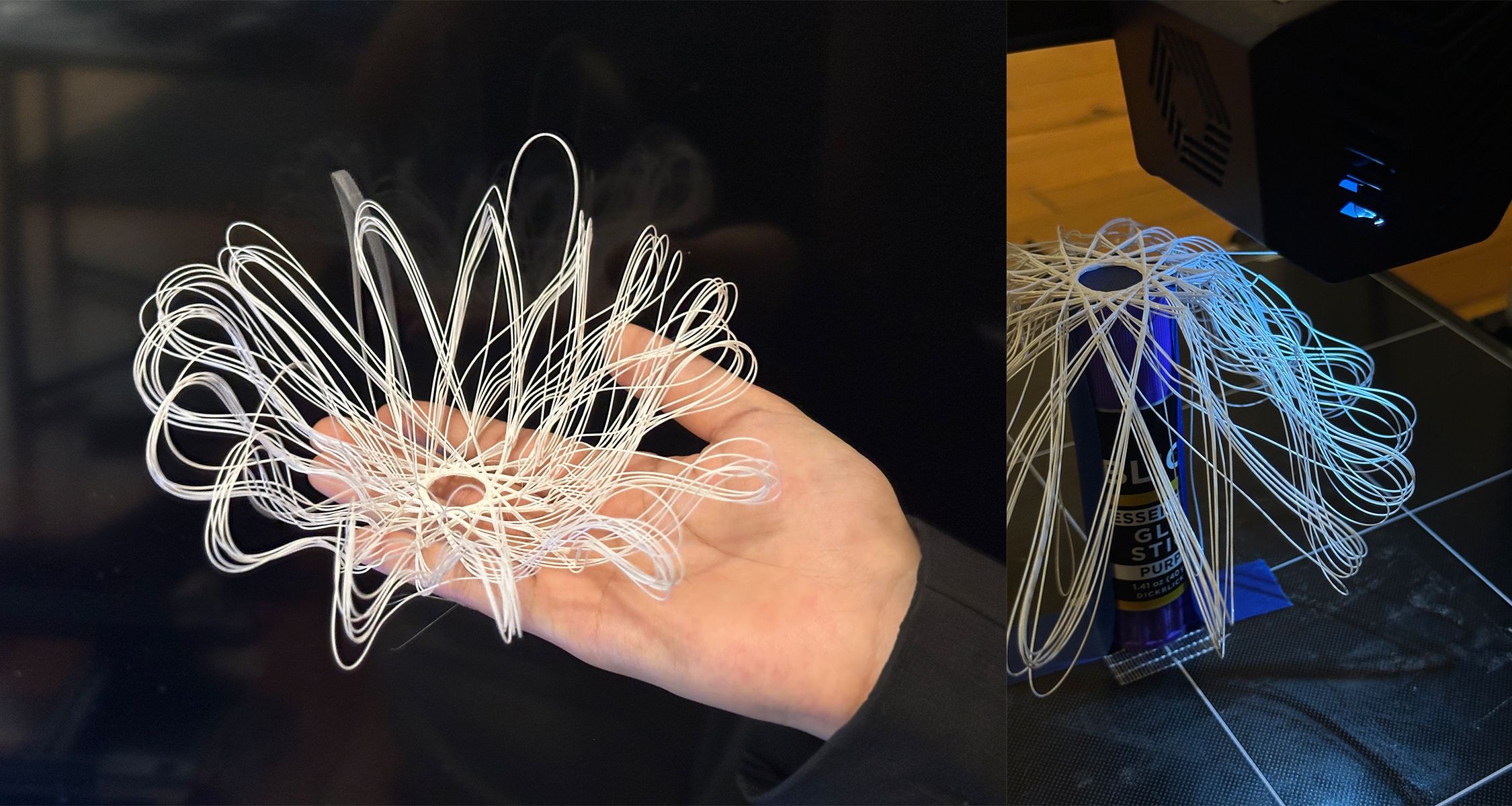

Using G-code, we explored new possibilities in 3D printing. Rather than printing with a traditional mesh, we experimented with creating patterns using single-line work. First, we generated the linework drawings using a function in Grasshopper. Once the line paths were converted to G-code, we reset the Z-axis and printed directly onto an elevated platform—the top of a glue stick. Throughout the process, we anticipated how gravity would influence the print and curated our setup to transform the 2D design into a 3D outcome. During printing, the filament began as a soft liquid when heated, dropping down before adhering to the surface and floating in the air as it cured with the help of a fan. This process allowed the 3D printer to create a three-dimensional "flower," even though the G-code only defined flat output. The adjustable speed not only make printing very efficient, with 4 minute maximum to finish printing a produce, while also subletly influence the form of the product. The result was a unique interplay of gravity, material properties, and digital design.